Yamazaki Mazak

Event: Mazak Visit

Number of pupils attending: 7

Aim of the activity

Our Careers adviser Paula Collins has set up a range of visits to local employers within and around Worcester to support our Year 10 students. Visit planned for students to:

Increase employer engagement

The workings of a workplace visit

Raise students’ aspirations

Raising industry sectors profile and appeal to students

Providing LMI learning Future apprenticeships

Linking Gatsby Benchmark 1, 2, 3, 4, 5 and 6.

Activity

Pupils were excited but nervous for their visit to Yamazaki Mazak UK Ltd, which is based at the European manufacturing plant in Worcester, which also houses the European Technology Centre (ETC) and is the UK’s largest and most expert team of engineers, with vast experience in machine tool applications for almost every industry sector.

We arrived prompt at 10am as we wanted to make a good impression and were greeted by Karen in the main area of reception. We were then taken to one of their executive rooms to have an overview of the company. We watched a PowerPoint presentation which gave an overview of the company, the countries they are situated in and how they make their money.

Karen spoke to the students about the products they make, how expensive the machinery is and how the company work on a day to day running. Their machinery makes knee and hip replacements, aeroplane parts as well as wind turbines.

We were taken on a tour of the production warehouse by a few apprentices’ warehouse and see on a first-hand basis the machinery being created. There were massive machines which they place a sheet of steel into, then programmed the computer and a laser cuts out the template. The robot can be reprogrammed to do many different jobs. The pupils were blown away by the technology and stood just gazing at the sheer size and magnitude of the machinery and what it could do.

The machinery is purposely built within the building due to them not being able to transport it to the production warehouse. These machines were huge and cost millions of pounds!! We were not allowed to take any photos due to the advance technology being used.

The pupils were fascinated by the whole experience.

Karen informed the students that many students complete work experience at the company, however it is highly sought after, and pupils must go through an interview process.

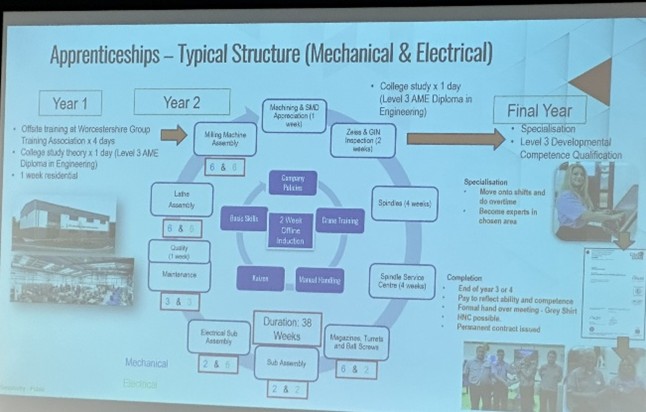

The company also have an apprenticeship scheme. To be considered, students need to have at least 2 GCSEs of grade 3 or above including English and Maths. It is a 3 to 4-year programme and they must wear a blue shirt so that they are identifiable on the shop floor. They work in all areas of the company and after 6 months they can choose the field they want to progress into. This gave our students lots to think about. They were surprised when they were informed that apprenticeships were given a financial adviser, as the jump from college to work is a big one and it stops them getting into financial debt and begin to manage their own finances.

Impact of activity

The students were engaged throughout and had never experienced anything like this. It showed them what they could achieve if they put their minds to it. The visit also exposed the students to different job roles within the company, from HR, cleaner, office staff to engineers.

Quotes from the students.

‘How much does an apprenticeship earn’

‘Does the machine work all the time’

‘Why has the room got temperatures displayed’

‘The machines need ventilation, so we have temperature gauges to ensure that the room is not overheating.’

‘How does the robot arm know to move’

Teachers feedback

The visit offered an invaluable opportunity to see how engineering theory translates into practice. It highlighted the diversity of roles within manufacturing and the importance of innovation in maintain global competitiveness. A few students expressed an interest in pursuing a career in manufacturing engineering.